10 Facility Manager Priorities for 2026 | Northeast Ohio FM Guide

The Facilities Management Landscape Is Changing — Fast

Facilities management is no longer a background function. By 2026, facility managers will be judged less on task completion and more on risk prevention, financial stewardship, compliance readiness, and strategic decision-making.

For facility leaders in Northeast Ohio, these pressures are amplified.

Aging infrastructure, extreme seasonal weather, labor shortages, tightening compliance requirements, and rising operational costs are forcing organizations to rethink how facilities are managed across healthcare, education, commercial, industrial, and public spaces.

This article outlines the 10 most critical focus areas every facility manager should prioritize in 2026 — not in theory, but in practical, operational terms relevant to Northeast Ohio.

Each section answers:

Why it matters

What happens if it’s ignored

What facility managers should be doing now

Deferred Maintenance Risk Management

Why Deferred Maintenance Will Be One of the Biggest FM Risks in 2026

Deferred maintenance increases operational costs, safety risks, and compliance exposure — especially in older Northeast Ohio facilities.

Deferred maintenance is no longer just a budgeting issue. By 2026, it will be a risk multiplier.

Across Northeast Ohio, many facilities were built decades ago. Aging roofs, mechanical systems, parking structures, plumbing, and electrical infrastructure are already operating beyond their intended lifecycle. When maintenance is postponed, small issues quietly become high-cost failures.

Facility managers are increasingly expected to quantify deferred maintenance risk, not just report it.

Two large, rusted industrial boilers sit in a dark, abandoned basement with concrete walls.

Why This Is a Northeast Ohio Issue

Freeze–thaw cycles accelerate structural wear

Heavy snow loads stress roofs and drainage systems

Older HVAC systems struggle with temperature extremes

Moisture intrusion leads to mold and indoor air quality issues

These regional factors make deferred maintenance especially dangerous for:

Hospitals and healthcare facilities

School districts and universities

Municipal and government buildings

Commercial and mixed-use properties

What Happens When Deferred Maintenance Is Ignored

Facility managers who delay maintenance often face:

Emergency repairs at 3–5x the planned cost

Increased safety incidents and liability exposure

Failed inspections and compliance violations

Operational downtime that disrupts occupants

By 2026, leadership teams will expect facility managers to prove they understand these risks in financial terms.

What Facility Managers Should Be Doing Now

To prepare for 2026, facility managers should:

Conduct facility condition assessments annually

Assign risk scores to deferred maintenance items

Prioritize life-safety and compliance-related assets

Translate deferred maintenance into budget impact language

Align maintenance plans with long-term capital forecasting

Deferred maintenance should no longer live in spreadsheets — it should live in executive conversations.

Extreme Weather Preparedness & Seasonal Planning

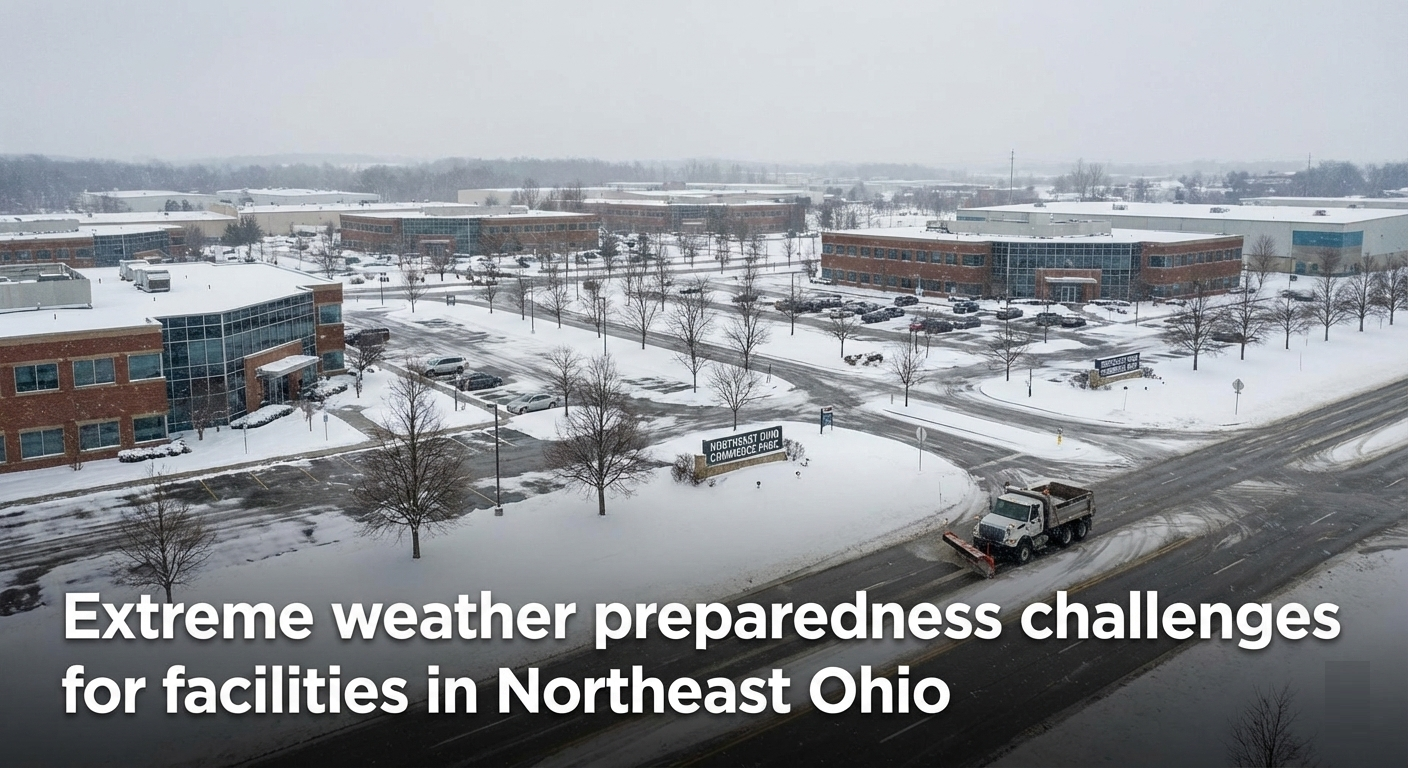

Why Extreme Weather Readiness Will Separate Strong Facility Teams from Reactive Ones in 2026

Facility managers who plan proactively for extreme weather reduce liability, downtime, and emergency costs—especially in regions like Northeast Ohio with high seasonal volatility.

By 2026, extreme weather will no longer be treated as an exception. It will be a baseline operational variable that facility managers are expected to plan for, budget against, and document.

For Northeast Ohio facilities, weather is not just inconvenient—it is operationally disruptive.

An aerial view of a snow-covered business park in Northeast Ohio with several brick buildings.

Why This Matters More in Northeast Ohio

Northeast Ohio presents one of the most challenging seasonal operating environments in the U.S.:

Heavy snowfall and ice accumulation

Freeze–thaw cycles that damage concrete, asphalt, and building envelopes

Intense spring rain leading to flooding and drainage failures

Summer heat waves stressing HVAC and electrical systems

Facilities in Cleveland, Akron, Canton, Youngstown, and surrounding counties must operate year-round under these conditions—often with limited staff and aging infrastructure.

By 2026, leadership teams will expect facility managers to anticipate weather-related risks, not simply respond after damage occurs.

The Real Cost of Poor Seasonal Planning

Facilities that lack structured weather preparedness often experience:

Slip-and-fall incidents and legal claims

Roof collapses due to snow load mismanagement

Parking lot deterioration from untreated freeze damage

Flooding caused by blocked drains and failing infrastructure

Emergency vendor callouts at premium rates

These costs rarely show up as “weather failures” in reports—they appear as unplanned expenses, insurance claims, and operational disruptions.

What Effective Weather Preparedness Looks Like in 2026

Forward-thinking facility managers are shifting from reactive responses to seasonal operating frameworks.

This includes:

Pre-winter inspections of roofs, drains, and exterior systems

Documented snow and ice response plans

Vendor readiness verification before peak seasons

Spring and fall transition checklists

Weather-related risk logs tied to incident prevention

In 2026, preparedness will be measured not by how fast teams respond—but by how few emergencies occur.

Seasonal Planning Is Also a Compliance and Liability Issue

Weather-related incidents increasingly intersect with:

OSHA safety expectations

Insurance requirements

Risk management audits

Tenant and occupant safety standards

Facility managers must be able to demonstrate:

Preventive planning

Documented response procedures

Vendor accountability

Incident prevention measures

In high-risk environments like healthcare, education, and public facilities, weather readiness is no longer optional—it is a duty of care.

What Facility Managers Should Be Doing Now

To prepare for 2026, facility managers in Northeast Ohio should:

Develop season-specific operational playbooks

Conduct pre-season risk assessments

Align snow, landscaping, and exterior maintenance vendors early

Budget proactively for seasonal services

Track weather-related incidents and near-misses

Weather preparedness should be treated as a core facilities competency, not a seasonal scramble.

Vendor Performance Tracking & Consolidation

Why Vendor Management Will Be a Core FM Competency by 2026

Facility managers who actively track vendor performance and consolidate services reduce costs, improve service quality, and lower operational risk.

By 2026, facilities management success will be closely tied to how well vendors are managed, not how many are hired.

For many facility teams in Northeast Ohio, vendor sprawl has quietly become a problem: multiple contractors, inconsistent standards, overlapping scopes, unclear accountability, and rising costs with little performance visibility.

What once felt like flexibility is now an operational liability.

Two facility managers in safety vests review documents outdoors near a snow-plowing operation.

The Hidden Risks of Poor Vendor Oversight

Facilities that lack structured vendor performance tracking often face:

Inconsistent service quality across sites

Missed scope details and undocumented work

Delayed response times during emergencies

Budget overruns caused by change orders

Increased liability due to unclear responsibility

In regions like Cleveland, Akron, and surrounding counties, where weather, aging infrastructure, and compliance pressures are high, weak vendor management compounds existing risk.

By 2026, facility managers will be expected to prove vendor value, not just manage invoices.

Why Vendor Consolidation Is Gaining Momentum

Vendor consolidation is becoming a strategic priority across:

Healthcare systems

School districts and universities

Commercial property portfolios

Municipal and public-sector facilities

The goal is not fewer vendors for convenience — it is fewer vendors with clearer accountability.

Benefits of consolidation include:

Standardized service levels

Simplified communication and reporting

Improved response coordination

Better cost predictability

Stronger long-term partnerships

In Northeast Ohio, consolidation also improves seasonal readiness, especially for services like snow removal, landscaping, cleaning, and exterior maintenance.

What Vendor Performance Tracking Looks Like in 2026

Forward-thinking facility managers are moving beyond informal feedback and toward measurable performance systems.

Key tracking areas include:

Response times

Scope compliance

Safety performance

Documentation accuracy

Cost control

Seasonal preparedness

These metrics allow facility leaders to:

Identify underperforming vendors early

Justify vendor changes with data

Support budget and contract negotiations

Reduce operational surprises

Vendor performance is no longer subjective — it is reportable.

Northeast Ohio Considerations for Vendor Strategy

Facility managers in Northeast Ohio should account for:

Regional labor shortages affecting vendor reliability

Weather-driven service variability

Aging facilities requiring specialized experience

Local compliance and safety standards

Selecting vendors who understand the regional operating environment is increasingly critical.

Local knowledge is not a bonus — it is a risk mitigation tool.

What Facility Managers Should Be Doing Now

To prepare for 2026, facility managers should:

Audit current vendor lists and overlapping scopes

Define clear performance expectations and KPIs

Standardize contracts and service-level agreements

Track vendor performance consistently

Identify opportunities to consolidate services strategically

Strong vendor management frees facility teams to focus on strategy instead of firefighting.

Budget Forecasting & Cost Control

Why Budget Accuracy Will Matter More Than Budget Size in 2026

Facility managers who can accurately forecast costs and control spend will be valued as strategic partners, not cost centers.

By 2026, facilities budgets will face increased scrutiny. Rising labor costs, inflationary pressures, energy volatility, and deferred maintenance are forcing organizations to demand greater financial predictability from facility leaders.

For facility managers in Northeast Ohio, cost control is especially complex due to:

Seasonal service fluctuations

Aging infrastructure requiring capital investment

Weather-driven emergency spending

Vendor cost variability

Leadership teams will no longer accept reactive explanations — they will expect forecast-driven decision-making.

A facility manager analyzes budget forecasting data and charts on a laptop in an office.

The Shift from “Staying Within Budget” to “Explaining the Budget”

Historically, facility managers were judged on whether they stayed within budget. In 2026, the expectation changes.

Facility managers must be able to:

Explain why costs changed

Forecast where future costs will rise

Justify when spending should be accelerated or delayed

This requires a shift from expense tracking to financial storytelling.

Common Budgeting Gaps in Facilities Management

Many facilities still struggle with:

Flat year-over-year budgeting that ignores asset condition

Lack of seasonal cost modeling

Poor visibility into vendor-driven expenses

Reactive emergency spending

Disconnect between maintenance and capital planning

These gaps make budgets fragile — especially in regions like Northeast Ohio, where winter-related costs alone can derail annual forecasts.

What Strong FM Budget Forecasting Looks Like in 2026

Effective facility budget forecasting integrates:

Asset lifecycle data

Deferred maintenance risk

Seasonal service cost modeling

Vendor contract analysis

Energy usage trends

Rather than static spreadsheets, forward-looking facility managers use rolling forecasts that adapt to changing conditions.

This approach allows leadership to see:

Trade-offs between preventive and emergency spending

Long-term cost avoidance opportunities

Capital planning priorities

Cost Control Without Cutting Corners

Cost control in 2026 is not about cutting services — it’s about spending smarter.

High-performing facility teams focus on:

Preventive maintenance to avoid failures

Vendor consolidation to reduce redundancy

Energy efficiency initiatives with measurable ROI

Data-driven decision-making

In Northeast Ohio, proactive snow planning, landscaping coordination, and infrastructure upkeep can significantly reduce emergency costs.

What Facility Managers Should Be Doing Now

To strengthen budget control ahead of 2026, facility managers should:

Align maintenance plans with financial forecasts

Track costs by asset, not just by department

Separate planned vs unplanned spending clearly

Build weather-related contingencies into budgets

Communicate budget implications in business terms

Facilities leaders who master budgeting will increasingly be seen as risk managers and financial stewards, not overhead.

Compliance Documentation & Audits

Why Compliance Readiness Will Be Non-Negotiable for Facility Managers in 2026

Facility managers who maintain clear, up-to-date compliance documentation reduce legal risk, avoid failed audits, and protect their organizations from costly violations.

By 2026, facilities compliance will no longer be treated as an occasional audit event. It will be an always-on operational requirement.

Regulatory expectations are increasing across healthcare, education, commercial, and public facilities. Facility managers are now expected to produce documentation quickly, accurately, and consistently—not scramble when an inspection occurs.

A professional man in a suit uses a digital tablet to review facility management data.

Why Compliance Pressure Is Increasing in Northeast Ohio

Facilities in Northeast Ohio face heightened scrutiny due to:

Aging infrastructure and legacy systems

Weather-related safety risks (ice, snow, flooding)

OSHA and safety enforcement trends

Insurance carrier documentation requirements

Public-sector and healthcare regulatory oversight

In cities like Cleveland, Akron, and Canton, inspections increasingly focus on whether risks were anticipated and documented, not just whether issues were fixed afterward.

Common Compliance Gaps in Facilities Management

Many facility teams still struggle with:

Incomplete maintenance records

Inconsistent vendor documentation

Lack of safety inspection logs

Poor incident and near-miss reporting

Missing proof of preventive maintenance

These gaps expose organizations to:

Failed inspections

Insurance disputes

Legal liability

Reputational damage

In 2026, “we fixed it” will no longer be enough—facility managers will need to show when, how, and why decisions were made.

What Strong Compliance Documentation Looks Like in 2026

High-performing facility teams maintain:

Centralized documentation systems

Time-stamped maintenance and inspection logs

Vendor compliance certificates and insurance records

Safety training documentation

Incident and corrective-action reports

This documentation serves multiple purposes:

Audit readiness

Risk management

Budget justification

Leadership reporting

Compliance is no longer administrative—it is strategic protection.

Audits Are Becoming Continuous, Not Periodic

By 2026, many organizations will adopt:

Rolling internal audits

Digital compliance dashboards

Third-party risk assessments

Facility managers who proactively audit their own operations gain:

Early visibility into risk

Greater control over outcomes

Stronger credibility with leadership

In Northeast Ohio, where facilities face both environmental and regulatory complexity, this proactive stance is becoming a competitive advantage.

What Facility Managers Should Be Doing Now

To prepare for 2026, facility managers should:

Standardize documentation processes across sites

Ensure vendors meet and document compliance requirements

Conduct internal compliance reviews regularly

Train teams on documentation best practices

Treat audits as operational checkpoints, not emergencies

Strong documentation turns compliance from a burden into a defensive asset.

Energy Efficiency & Sustainability Mandates

Why Energy Efficiency Will Shift from “Nice to Have” to Operational Requirement by 2026

Facility managers who prioritize energy efficiency reduce operating costs, meet regulatory expectations, and protect long-term asset value.

By 2026, sustainability will no longer be driven by branding or optional initiatives. It will be driven by cost pressure, regulatory requirements, and stakeholder expectations.

Energy efficiency is becoming one of the few areas where facility managers can directly influence operating expenses while also meeting environmental and compliance goals.

The Northeast Ohio Energy Reality

Facilities in Northeast Ohio face unique energy challenges:

Cold winters driving high heating demand

Hot, humid summers increasing cooling loads

Older buildings with outdated insulation and HVAC systems

Rising utility costs and volatile energy pricing

For many facilities in Cleveland, Akron, and surrounding counties, inefficient energy systems represent one of the largest controllable cost leaks.

By 2026, leadership will expect facility managers to understand—and actively manage—this exposure.

Sustainability Is Becoming a Compliance and Reporting Issue

Energy efficiency is increasingly tied to:

ESG reporting requirements

Public-sector sustainability mandates

Healthcare and education accreditation standards

Investor and board-level oversight

Facility managers are now expected to provide:

Measurable energy performance data

Documented efficiency improvements

Clear ROI justifications

Sustainability without data will no longer be credible.

What Practical Energy Efficiency Looks Like in 2026

Forward-thinking facility teams focus on:

HVAC optimization and preventative tuning

Lighting upgrades and controls

Building envelope improvements

Energy benchmarking and monitoring

Vendor accountability for energy-impacting services

Rather than chasing large capital projects immediately, many Northeast Ohio facilities start with operational efficiency improvements that deliver faster returns.

The Cost of Ignoring Energy Efficiency

Facilities that fail to address energy performance face:

Escalating utility costs

Increased strain on aging systems

Reduced asset lifespan

Difficulty meeting future mandates

By 2026, energy inefficiency will be viewed not just as waste—but as poor facilities governance.

What Facility Managers Should Be Doing Now

To prepare for 2026, facility managers should:

Benchmark current energy usage

Identify high-impact efficiency opportunities

Integrate energy goals into maintenance planning

Track savings and performance improvements

Communicate energy results in financial terms

Energy efficiency is no longer about being “green.”

It’s about being operationally disciplined.

Technology Adoption (CMMS, IoT & Operational Dashboards)

Why Technology Will Be Expected — but Not Excused — by 2026

Facility managers who adopt the right technology improve visibility, reduce downtime, and make defensible decisions—without adding operational complexity.

By 2026, technology adoption in facilities management will no longer be optional. However, facility leaders will not be rewarded for having tools only for using them effectively.

The challenge for many facility managers is not access to technology, but implementation discipline.

A facility manager in a safety vest uses a tablet to monitor industrial mechanical equipment.

The Technology Gap in Facilities Management

Many facilities still rely on:

Spreadsheets and email-based work orders

Paper inspection logs

Informal vendor communication

Manual reporting to leadership

These approaches limit visibility, slow decision-making, and increase compliance risk—especially in multi-site or weather-impacted environments like Northeast Ohio.

What Practical FM Technology Looks Like in 2026

High-performing facility teams focus on core functionality, not feature overload.

Key tools include:

CMMS platforms for work order tracking, asset history, and preventive maintenance

IoT sensors for monitoring critical systems (HVAC, leaks, temperature)

Operational dashboards for real-time reporting to leadership

These tools allow facility managers to shift from anecdotal explanations to data-backed insights.

Northeast Ohio Use Cases for FM Technology

Technology adoption is particularly valuable in Northeast Ohio for:

Monitoring HVAC performance during extreme temperature swings

Tracking snow and weather-related service response

Managing aging assets with limited capital budgets

Supporting compliance documentation and audits

When used correctly, technology reduces both risk and manual workload.

The Biggest Technology Mistakes Facility Managers Make

Common pitfalls include:

Implementing too many systems at once

Failing to train staff properly

Using technology without clear objectives

Not integrating tools into daily workflows

By 2026, ineffective tech adoption will be viewed as a leadership issue—not a resource issue.

What Facility Managers Should Be Doing Now

To prepare for 2026, facility managers should:

Identify one or two high-impact technology gaps

Select tools that align with actual workflows

Train teams consistently and document usage

Use dashboards to communicate value to leadership

Review and refine systems regularly

Technology should simplify operations—not complicate them.

Workforce Training & Retention

Why People Will Be the Most Constrained FM Resource in 2026

Facility managers who invest in training and retention reduce operational risk, maintain service quality, and stabilize costs in a tight labor market.

By 2026, workforce challenges will be one of the largest limiting factors in facilities management. Labor shortages, skill gaps, and turnover are already affecting service reliability across the sector.

For facility managers in Northeast Ohio, these pressures are intensified by:

An aging skilled trades workforce

Increased competition for maintenance talent

Rising labor costs

Reliance on third-party vendors with staffing constraints

Facilities that ignore workforce strategy will experience declining performance regardless of budget or technology.

The Hidden Cost of Turnover in Facilities Operations

High turnover creates more than staffing gaps—it introduces risk.

Common consequences include:

Missed preventive maintenance

Inconsistent safety practices

Knowledge loss around building systems

Increased reliance on emergency vendors

Higher long-term labor costs

By 2026, leadership will increasingly expect facility managers to manage people risk, not just headcount.

What Workforce Readiness Looks Like in 2026

High-performing facility teams focus on:

Cross-training staff to reduce single points of failure

Clear standard operating procedures (SOPs)

Ongoing safety and compliance training

Structured onboarding and skill development

In Northeast Ohio, where weather and infrastructure complexity demand versatility, workforce readiness is a core operational requirement.

Training Is a Risk Mitigation Strategy

Training is often viewed as a cost, but in facilities management it is a control mechanism.

Well-trained teams:

Respond faster to issues

Prevent incidents before they escalate

Reduce reliance on external contractors

Improve compliance outcomes

By 2026, undertrained teams will be seen as an avoidable operational risk.

Retention Requires More Than Competitive Pay

While compensation matters, retention is increasingly influenced by:

Predictable schedules

Clear expectations

Access to tools and training

Feeling supported by leadership

Facility managers who create stable, well-organized operations are more likely to retain talent—even in competitive labor markets like Northeast Ohio.

What Facility Managers Should Be Doing Now

To prepare for 2026, facility managers should:

Identify critical skill gaps within teams

Invest in cross-training and documentation

Strengthen onboarding processes

Partner with reliable vendors for workforce support

Treat retention as an operational KPI

Facilities succeed when the people behind them are prepared, supported, and retained.

Safety, Liability & Incident Prevention

Why Safety Will Be a Board-Level FM Priority in 2026

By 2026, facility safety will be directly tied to organizational risk, insurance costs, and executive accountability.

Safety is no longer viewed as a checklist item or compliance exercise. In today’s environment, a single incident can result in:

Legal exposure

Insurance premium increases

Reputational damage

Operational disruption

For facility managers, safety is now a strategic responsibility, not just an operational one.

The Expanding Liability Landscape for Facility Managers

Facility-related incidents are becoming more costly due to:

Stricter regulatory enforcement

Higher litigation frequency

Increased documentation expectations

Public visibility via social media and reporting platforms

In Northeast Ohio, where facilities face seasonal weather risks, aging infrastructure, and high foot traffic in healthcare, education, and commercial properties, liability exposure is amplified.

Common Safety Gaps Facilities Must Eliminate Before 2026

Many incidents are not caused by sudden failures—but by overlooked basics.

High-risk gaps include:

Poorly documented inspections

Inconsistent incident reporting

Deferred repairs creating trip and fall hazards

Inadequate lighting and signage

Limited emergency response planning

Facility managers who fail to close these gaps may struggle to justify decisions during audits or legal reviews.

Incident Prevention Starts with Data, Not Reaction

Reactive safety management increases costs and risk.

Proactive facilities:

Track incidents and near-misses

Analyze recurring patterns

Address root causes instead of symptoms

Integrate safety checks into preventive maintenance

By 2026, leadership will expect facility managers to demonstrate prevention, not just response.

Weather-Driven Risk in Northeast Ohio Facilities

Few regions experience the seasonal variability of Northeast Ohio.

Facility safety strategies must account for:

Snow and ice accumulation

Freeze-thaw cycles damaging walkways

Power outages during storms

HVAC strain during extreme temperature swings

Failing to prepare for seasonal risk increases incident frequency and liability exposure—especially in healthcare, education, and public-facing facilities.

Documentation Is the New Defense

In 2026, documentation will matter as much as action.

Facilities must be able to show:

Inspection logs

Maintenance records

Incident reports

Vendor compliance documentation

Corrective action timelines

Well-documented facilities reduce legal exposure and strengthen executive confidence.

Safety as a Leadership Communication Tool

Facility managers who communicate safety performance effectively:

Gain trust from executives

Support budget requests

Reduce scrutiny during incidents

Position facilities as risk mitigators, not cost centers

Safety metrics are increasingly used to evaluate leadership effectiveness.

What Facility Managers Should Be Doing Now

To prepare for 2026, facility managers should:

Audit current safety programs and documentation

Standardize inspection and reporting processes

Align vendors with safety expectations

Integrate weather-based risk planning

Treat safety metrics as executive-level reporting tools

Safety is not optional—and it is no longer invisible.

Communicating Facility Value to Executive Leadership

Why Facility Managers Must Shift from Operators to Strategic Communicators in 2026

In 2026, facility managers who cannot clearly communicate value in business terms will be overlooked—regardless of how well buildings are run.

Facilities work has always been essential, but it has not always been visible. The challenge moving forward is not execution—it is translation.

Executives do not think in work orders, inspections, or square footage. They think in:

Risk

Cost

Continuity

Compliance

Reputation

Facility managers who align their language to these priorities will earn influence, trust, and budget authority.

Why “Everything Is Fine” Is the Wrong Message

When facility leaders say:

“Nothing’s wrong. Everything is running.”

Executives often hear:

“Facilities are not a strategic concern.”

In reality, well-run facilities:

Prevent financial loss

Reduce liability exposure

Enable workforce productivity

Support regulatory compliance

Protect brand reputation

The value exists—but it must be articulated intentionally.

Translating Facility Work into Executive Metrics

By 2026, facility leaders must connect daily operations to outcomes executives understand.

Examples:

Preventive maintenance → Reduced downtime and repair costs

Safety audits → Lower insurance exposure

Vendor consolidation → Operational efficiency

Energy upgrades → Long-term cost control

Compliance readiness → Risk mitigation

Facilities that fail to quantify value are often first on the list when budgets tighten.

Using Data to Build Executive Confidence

Facility managers should treat reporting as a leadership tool—not an administrative task.

Effective executive reporting includes:

Trends, not just snapshots

Risks avoided, not just issues resolved

Cost savings from preventive actions

Compliance status and audit readiness

Forecasted needs tied to business goals

In Northeast Ohio—where facilities face aging infrastructure, seasonal risks, and compliance pressure—data-driven storytelling matters even more.

Aligning Facility Strategy with Organizational Goals

Facilities should never operate in isolation.

By 2026, successful facility leaders will align with:

Growth plans (new locations, expansions)

Workforce needs (safety, comfort, productivity)

Sustainability targets

Financial planning cycles

Risk management frameworks

Facilities become strategic when they support where the organization is going—not just where it is.

From Cost Center to Risk Shield

One of the most powerful reframes for executive audiences is this:

Facilities are not a cost center.

They are a risk shield.

Well-managed facilities:

Prevent lawsuits

Reduce downtime

Protect assets

Ensure regulatory compliance

Maintain public trust

This perspective changes how executives view investment decisions.

The Facility Manager’s Leadership Opportunity in 2026

Facility managers who:

Communicate clearly

Report strategically

Anticipate risk

Tie actions to outcomes

Will move from reactive roles into trusted leadership positions.

Those who do not may find their expertise undervalued—not because it lacks importance, but because it lacks visibility.

What Facility Managers Should Do Before 2026

To strengthen executive communication:

Standardize reporting dashboards

Prepare quarterly facility risk summaries

Quantify cost avoidance and savings

Align language with leadership priorities

Document impact—not just activity

Visibility is not self-promotion.

It is responsible leadership.

Preparing Facility Management for 2026 in Northeast Ohio

Facilities management in 2026 will demand more than technical expertise—it will require strategic vision, operational discipline, and executive-level communication. Facility managers in Northeast Ohio face unique challenges: aging infrastructure, seasonal weather extremes, labor constraints, rising energy costs, and stricter compliance requirements.

Success will come to those who can integrate these 10 priorities into a cohesive operational strategy:

Deferred Maintenance Risk Management – Proactively assess and mitigate aging asset risks before they become crises.

Extreme Weather Preparedness & Seasonal Planning – Align maintenance, staffing, and vendor strategies with Northeast Ohio’s seasonal variability.

Vendor Performance Tracking & Consolidation – Standardize expectations, monitor KPIs, and consolidate vendors for consistency and cost efficiency.

Budget Forecasting & Cost Control – Use predictive financial planning to justify investments, control spending, and prevent emergency costs.

Compliance Documentation & Audits – Maintain continuous, accurate records to reduce liability and ensure audit readiness.

Energy Efficiency & Sustainability Mandates – Implement practical energy-saving measures that provide measurable ROI and regulatory alignment.

Technology Adoption (CMMS, IoT, Dashboards) – Leverage technology strategically to increase visibility, prevent downtime, and drive data-based decisions.

Workforce Training & Retention – Invest in skills development, cross-training, and retention programs to reduce operational risk.

Safety, Liability & Incident Prevention – Treat safety as a core operational KPI, not just a compliance requirement.

Communicating Facility Value to Executive Leadership – Translate operations into measurable business outcomes that influence decisions and secure leadership support.

Executive Takeaways

Proactivity Wins: Delaying maintenance, training, or reporting will cost more in 2026 than any efficiency gained.

Data Is Your Language: Executives respond to metrics, risk assessments, and ROI—not anecdotal updates.

Regional Awareness Matters: Northeast Ohio’s weather, aging buildings, and labor market create unique risks that must be incorporated into every operational plan.

People Are Assets: Skilled, well-trained staff and reliable vendors are the foundation of every strategic FM initiative.

Communication Creates Value: Facility managers who quantify impact and report effectively move from operational roles into strategic leadership positions.

Facility management in Northeast Ohio is evolving from reactive task management to strategic enterprise leadership. By focusing on these 10 priorities, facility managers will protect assets, reduce costs, mitigate risk, and elevate the perceived value of their role to the executive team.

Frequently Asked Questions (FAQs)

1. What should facility managers in Northeast Ohio focus on in 2026?

Facility managers in Northeast Ohio should focus on 10 key areas: deferred maintenance, extreme weather preparedness, vendor management and consolidation, budget forecasting and cost control, compliance documentation, energy efficiency and sustainability, technology adoption (CMMS, IoT, dashboards), workforce training and retention, safety and incident prevention, and effectively communicating facility value to executive leadership.

2. Why is deferred maintenance a critical concern for facility managers?

Deferred maintenance can increase operational risk, create safety hazards, and lead to higher long-term costs. Proactively addressing aging infrastructure and scheduling preventive maintenance reduces emergency repairs and protects assets.

3. How can facility managers prepare for extreme weather in Northeast Ohio?

Facility managers should implement seasonal planning, pre-winter inspections, vendor readiness checks, emergency protocols, and risk tracking. These measures help minimize downtime, reduce liability, and prevent costly emergency repairs caused by snow, ice, flooding, or temperature extremes.

4. What technologies should facility managers adopt by 2026?

Key technologies include:

CMMS (Computerized Maintenance Management Systems) for work orders and asset tracking

IoT sensors to monitor critical building systems

Operational dashboards to track KPIs, costs, and maintenance performance

These tools help managers make data-driven decisions, prevent downtime, and communicate value to executives.

5. How can facility managers improve workforce training and retention?

Managers should:

Cross-train staff to reduce single points of failure

Document standard operating procedures (SOPs)

Provide ongoing safety and compliance training

Improve onboarding and mentoring

Offer predictable schedules and a supportive work environment

Investing in staff reduces operational risk and improves service reliability.

6. Why is communicating facility value to executives important?

Facility managers need to translate operational work into measurable business outcomes, such as cost savings, risk mitigation, compliance, and productivity. Clear communication elevates facilities from a cost center to a strategic leadership function, ensuring funding and executive support.

7. How can facility managers ensure compliance and audit readiness?

Facility managers should maintain centralized documentation for inspections, maintenance, vendor compliance, and incidents. Regular internal audits, staff training, and standardized reporting ensure that facilities are always prepared for regulatory inspections and audits.

8. What are the top safety priorities for facility managers in 2026?

Top safety priorities include:

Preventing incidents through regular inspections

Identifying and mitigating hazards

Tracking and reporting near-misses and incidents

Planning for seasonal weather risks

Documenting corrective actions and safety compliance

A proactive safety program reduces liability, protects staff and occupants, and builds executive confidence.