Mastering Predictive Maintenance with CMMS: The Future of Facility Management

Why Predictive Maintenance Is Reshaping Facility Management

Facility management is entering a data-driven era. Traditional reactive maintenance (“fix it when it breaks”) and even scheduled preventive maintenance are no longer enough to meet today’s expectations around uptime, safety, cost control, and sustainability. Industry data consistently shows that reactive maintenance can cost 3–5 times more than planned maintenance due to unplanned downtime, emergency labor, and secondary asset damage.

Predictive maintenance—powered by Computerized Maintenance Management Systems (CMMS)—is rapidly becoming the new standard. Organizations that adopt predictive maintenance strategies report up to 30–40% reductions in maintenance costs, 20–25% fewer equipment failures, and 10–20% longer asset life cycles compared to traditional approaches. These gains translate directly into improved operational resilience and budget predictability.

For facility leaders, especially across commercial buildings, healthcare, education, and multi-site portfolios, the shift is strategic. Unplanned downtime alone is estimated to cost large facilities hundreds of thousands of dollars annually, while critical environments such as hospitals and campuses face added compliance, safety, and reputational risks when systems fail unexpectedly.

Predictive maintenance uses real-time asset data, historical trends, and condition-based monitoring to anticipate failures before they occur. When integrated with a CMMS, maintenance teams can prioritize work orders based on asset criticality, risk, and performance data—rather than fixed calendars or emergency calls.

At Immaculate Management Group (IMG), we see predictive maintenance not as a buzzword, but as a measurable competitive advantage. A CMMS-enabled predictive approach allows facility teams to shift 30–50% of maintenance activities from reactive to proactive over time—freeing resources, improving response times, and supporting IMG’s core differentiators: reliability, attention to detail, proactivity, and efficiency.

This article explores how predictive maintenance works, the role of CMMS technology, and why forward-thinking facility managers should adopt this approach now rather than later.

Understanding Maintenance Strategies — Reactive vs Preventive vs Predictive

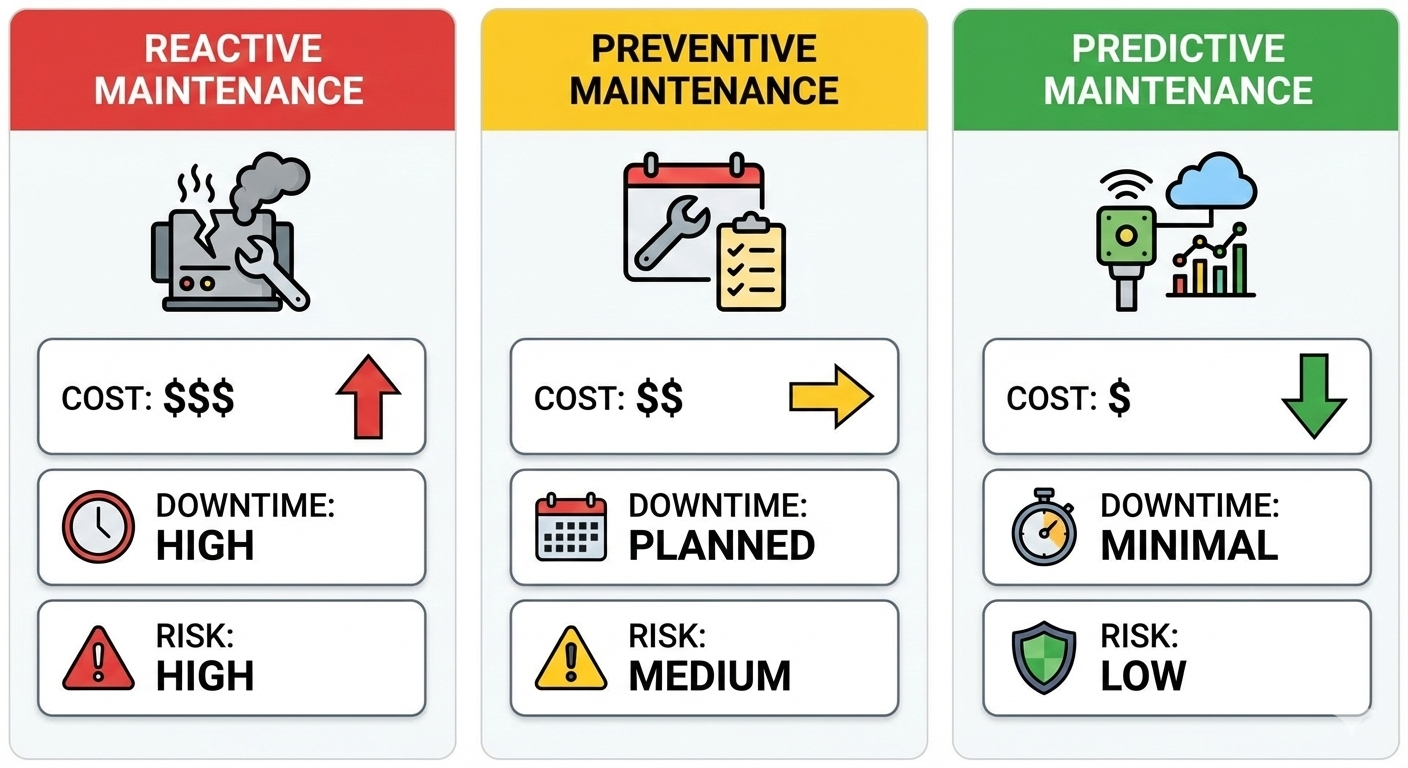

To fully appreciate the value of predictive maintenance, it’s important to understand how it differs from the two traditional maintenance models most facilities still rely on: reactive and preventive maintenance. Each approach has implications for cost, risk, asset performance, and operational efficiency.

Reactive Maintenance: High Risk, High Cost

Reactive maintenance follows a simple rule: fix assets only after they fail. While this approach may appear cost-effective in the short term, it is widely recognized as the most expensive and disruptive strategy over time.

Facilities operating primarily in reactive mode often experience:

Up to 5× higher repair costs due to emergency call-outs, expedited parts, and overtime labor

30–50% higher downtime, especially for critical HVAC, electrical, and mechanical systems

Increased safety incidents and compliance risks, particularly in healthcare and education environments

Industry benchmarks show that reactive maintenance can consume 40% or more of total maintenance budgets, while delivering the lowest return on asset reliability.

Preventive Maintenance: Better Control, Limited Precision

Preventive maintenance improves on reactive approaches by scheduling maintenance tasks at fixed intervals (monthly, quarterly, annually), regardless of actual asset condition. This method helps reduce failures but introduces inefficiencies of its own.

Common preventive maintenance challenges include:

Over-maintenance, where components are serviced or replaced before necessary

Under-maintenance, where failures still occur between scheduled intervals

Limited visibility into real-time asset health

On average, preventive maintenance reduces downtime by 20–30% compared to reactive maintenance. However, studies show that up to 30% of preventive maintenance tasks add little or no value, increasing labor and parts costs without improving outcomes.

Predictive Maintenance: Data-Driven and Performance-Focused

Predictive maintenance uses condition-based data—such as runtime hours, vibration, temperature, energy usage, and fault history—to determine when maintenance is actually needed. When enabled by a CMMS, this data is centralized, analyzed, and translated into prioritized work orders.

Key performance advantages include:

30–40% lower maintenance costs compared to reactive strategies

20–25% reduction in equipment failures

10–20% increase in asset lifespan

Improved planning accuracy and resource allocation

Instead of asking “When was this last serviced?”, predictive maintenance asks “What is this asset telling us right now?”

Why CMMS Is the Enabler

Without a CMMS, predictive maintenance is difficult to scale. A modern CMMS acts as the system of record and intelligence layer by:

Aggregating asset history, sensor data, and maintenance logs

Automating condition-based work orders

Ranking tasks by criticality, risk, and cost impact

Providing dashboards that show trends, failure patterns, and ROI

Facilities that implement CMMS-driven predictive maintenance typically shift 30–50% of work orders from reactive to proactive within the first 12–24 months.

For IMG and its clients, this transition supports smarter budgeting, reduced operational risk, and consistent service delivery across single-site and multi-site portfolios.

How CMMS Powers Predictive Maintenance

Predictive maintenance is only as effective as the system managing its data, workflows, and decisions. This is where a modern Computerized Maintenance Management System (CMMS) becomes essential. CMMS acts as the operational backbone that transforms raw asset data into actionable maintenance intelligence.

Without CMMS, predictive maintenance remains fragmented—data sits in spreadsheets, technician knowledge is siloed, and decision-making is reactive. With CMMS, facility teams gain a centralized platform that connects assets, people, processes, and performance metrics.

Centralized Asset Intelligence

A CMMS creates a single source of truth for every asset across a facility or portfolio. Each asset record contains:

Installation and warranty details

Service history and failure patterns

Runtime hours and usage trends

Compliance and inspection records

Facilities with centralized asset data report 15–20% faster fault diagnosis and significantly reduced reliance on institutional memory. Over time, this historical data enables CMMS platforms to identify recurring issues and predict future failures with greater accuracy.

Condition-Based Monitoring and Alerts

When integrated with meters, sensors, or building management systems (BMS), CMMS platforms can track condition indicators such as temperature, vibration, pressure, and energy consumption.

Instead of waiting for thresholds to be breached, CMMS can:

Trigger alerts when performance deviates from normal ranges

Automatically generate work orders before failure occurs

Escalate issues based on asset criticality

Organizations using condition-based CMMS alerts experience 25–35% fewer emergency work orders, allowing maintenance teams to plan interventions during low-impact windows.

Intelligent Work Order Automation

CMMS removes guesswork from task prioritization. Predictive maintenance rules allow the system to:

Assign work orders based on real-time asset condition

Rank tasks by risk, safety impact, and cost exposure

Allocate labor and parts efficiently

This automation improves wrench time and productivity. Industry benchmarks show CMMS-driven teams achieve 10–15% higher technician efficiency, while reducing backlog and response times.

Data-Driven Decision Making and Reporting

One of CMMS’s most powerful capabilities is performance visibility. Dashboards and reports provide insights into:

Mean Time Between Failures (MTBF)

Mean Time to Repair (MTTR)

Maintenance cost per asset

Reactive vs proactive work order ratios

Facility leaders who actively use CMMS analytics are better positioned to justify budgets, forecast capital replacements, and demonstrate ROI. Predictive programs supported by CMMS often show a return on investment within 12–18 months, driven by avoided downtime and extended asset life.

Scaling Predictive Maintenance Across Portfolios

For organizations managing multiple buildings or campuses, CMMS enables standardization. Maintenance strategies, asset hierarchies, and performance benchmarks can be applied consistently across locations.

This scalability is critical for IMG clients operating diverse portfolios, ensuring service reliability, compliance, and efficiency—without increasing headcount proportionally.

The Business Impact of Predictive Maintenance for Facility Leaders

Predictive maintenance is not just a technical upgrade—it is a business strategy. When supported by CMMS, it directly influences financial performance, risk management, compliance, and long-term asset planning. For facility leaders, the value lies in measurable outcomes rather than operational theory.

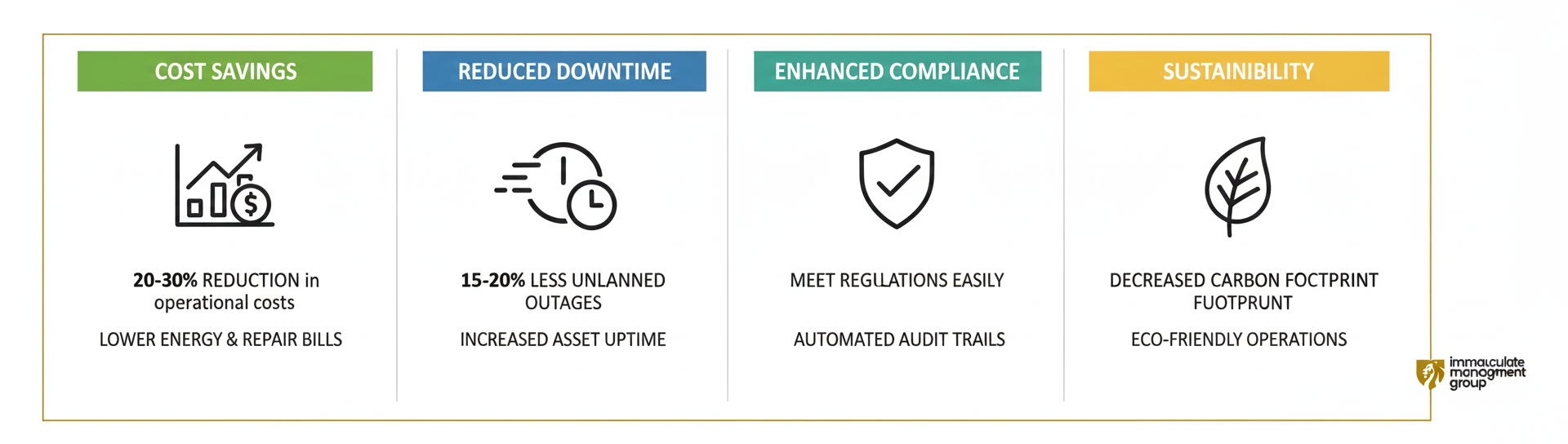

Cost Optimization and Budget Predictability

Unplanned maintenance is one of the biggest drivers of budget overruns in facility operations. Emergency repairs, expedited parts, and unplanned downtime can inflate annual maintenance spend by 20–30%.

Predictive maintenance helps organizations:

Reduce emergency maintenance costs by 30–40%

Lower total maintenance expenditure by 10–20% annually

Improve forecast accuracy for operating and capital budgets

With CMMS analytics, facility managers gain visibility into cost trends at asset, system, and portfolio levels—enabling data-backed budgeting instead of reactive justifications.

Reduced Downtime and Operational Risk

Downtime affects productivity, occupant satisfaction, and—in critical environments—safety. Predictive maintenance minimizes disruptions by addressing issues before failure.

Facilities using predictive maintenance report:

35–50% fewer unplanned outages

Shorter Mean Time to Repair (MTTR) by 15–25%

Improved service continuity across HVAC, electrical, plumbing, and life-safety systems

For healthcare, education, and commercial facilities, this reduction in downtime directly supports continuity of care, learning, and business operations.

Compliance, Safety, and Risk Management

Regulatory compliance and safety inspections place increasing pressure on facility teams. Missed inspections or undocumented maintenance activities can result in fines, insurance issues, and reputational damage.

CMMS-driven predictive maintenance supports compliance by:

Automatically scheduling condition-based inspections

Maintaining auditable maintenance records

Flagging high-risk assets before safety thresholds are breached

Organizations with digital maintenance records experience up to 50% faster audit preparation and significantly fewer compliance gaps.

Asset Longevity and Capital Planning

Replacing major assets prematurely is costly. Predictive maintenance extends asset lifespan by ensuring systems operate within optimal parameters.

On average, facilities adopting predictive maintenance achieve:

10–20% longer asset life cycles

Deferred capital replacement costs

More accurate capital expenditure (CapEx) planning

By using CMMS performance data, facility leaders can shift from age-based replacement to condition-based investment decisions—maximizing return on assets.

Sustainability and Energy Efficiency Gains

Poorly maintained equipment consumes more energy and generates higher emissions. Predictive maintenance identifies inefficiencies early, supporting sustainability goals.

Benefits include:

5–15% reductions in energy consumption

Lower carbon footprint through optimized equipment performance

Alignment with ESG and sustainability reporting requirements

For organizations prioritizing environmental responsibility, predictive maintenance becomes a practical lever—not just a policy statement.

Predictive Maintenance in Action — Industry-Specific Use Cases

While the principles of predictive maintenance remain consistent, its real value becomes clear when applied to specific facility environments. Different sectors face distinct risks, compliance demands, and asset criticality levels. CMMS-enabled predictive maintenance allows strategies to be tailored without losing consistency or control.

Healthcare Facilities: Reliability and Patient Safety

In healthcare environments, asset failure is not just an inconvenience—it can directly impact patient safety and care delivery. Critical systems such as HVAC, medical gas, power supply, and life-safety equipment must operate continuously.

Predictive maintenance supports healthcare facilities by:

Monitoring critical assets to prevent sudden failures

Reducing emergency maintenance by up to 40%

Improving compliance with regulatory and accreditation requirements

Extending the life of high-value clinical and support equipment

Hospitals using CMMS-driven predictive programs report higher system uptime, improved audit readiness, and fewer service disruptions in patient-care areas.

Educational Campuses: Scale, Consistency, and Cost Control

Universities and school districts manage large, diverse portfolios that include classrooms, laboratories, residence halls, and sports facilities—often with limited maintenance budgets.

Predictive maintenance enables education facilities to:

Prioritize assets based on usage patterns and academic calendars

Reduce deferred maintenance backlog by 15–25%

Minimize disruptions during teaching and examination periods

Standardize maintenance practices across multiple buildings

CMMS dashboards provide campus facility leaders with portfolio-wide visibility, enabling smarter resource allocation without increasing staff levels.

Commercial and Office Buildings: Uptime and Tenant Satisfaction

For commercial facilities, downtime directly affects tenant satisfaction, lease retention, and brand reputation. HVAC, elevators, and electrical systems are among the most common sources of tenant complaints.

Predictive maintenance helps commercial property managers:

Reduce tenant-impacting failures by 30–45%

Improve response times and service reliability

Support premium service-level agreements (SLAs)

Control operating expenses across multi-tenant environments

CMMS-driven insights also support transparent communication with tenants regarding maintenance planning and service performance.

Manufacturing and Industrial Facilities: Performance and Throughput

Although traditionally associated with manufacturing, predictive maintenance principles are increasingly applied to facility infrastructure within industrial environments.

Key benefits include:

Reduced production interruptions linked to facility system failures

Improved coordination between maintenance and operations teams

Higher asset availability and throughput

Predictive programs supported by CMMS can reduce facility-related downtime by up to 50%, directly protecting production output.

Multi-Site Portfolios: Standardization Without Rigidity

Organizations managing multiple sites—such as healthcare networks, retail chains, and education systems—often struggle with inconsistent maintenance practices.

CMMS enables:

Standard asset hierarchies and maintenance workflows

Cross-site performance benchmarking

Centralized reporting with local execution flexibility

For IMG clients, this means scalable predictive maintenance strategies that deliver consistent results across regions while respecting site-specific needs.

Common Challenges, Pitfalls, and How Facility Leaders Can Avoid Them

While predictive maintenance powered by CMMS delivers measurable value, many initiatives underperform due to avoidable execution gaps. Understanding these challenges upfront allows facility leaders to plan realistically and protect ROI.

Challenge 1: Expecting Technology to Replace Strategy

One of the most common pitfalls is assuming that installing a CMMS automatically delivers predictive maintenance benefits. In reality, CMMS is an enabler—not the strategy itself.

Risk:

High software adoption but low operational impact

Teams revert to reactive habits despite new tools

How to avoid it:

Define clear business objectives (downtime reduction, cost control, compliance)

Align CMMS configuration with operational priorities

Reinforce predictive thinking through leadership communication and KPIs

Image suggestion:

A visual showing technology at the center, surrounded by people, process, and strategy.

Challenge 2: Poor Data Quality and Asset Visibility

Predictive maintenance depends on accurate, structured data. Incomplete asset records or inconsistent naming conventions undermine analytics and automation.

Risk:

False alerts or missed failure signals

Low trust in CMMS insights

How to avoid it:

Start with critical assets rather than the full portfolio

Standardize asset hierarchies and data fields

Schedule periodic data audits within CMMS

Facilities that prioritize data governance see 20–30% higher reliability in predictive insights.

Image suggestion:

A before-and-after comparison of unstructured vs structured asset data in CMMS.

Challenge 3: Weak Sales–Operations Alignment

Predictive maintenance insights lose value if they are not acted upon quickly or consistently. This is especially true when CMMS insights inform service prioritization or contract discussions.

Risk:

Missed opportunities to intervene before failure

Delayed decision-making and reduced trust in the system

How to avoid it:

Define clear response-time SLAs

Establish ownership for high-risk alerts and insights

Review CMMS performance data jointly across teams

Challenge 4: Scaling Too Fast

Trying to apply predictive maintenance to every asset too early can overwhelm teams and dilute focus.

Risk:

Alert fatigue

Reduced adoption by technicians

How to avoid it:

Pilot predictive maintenance on high-impact systems

Measure results before expanding

Scale gradually across asset classes and sites

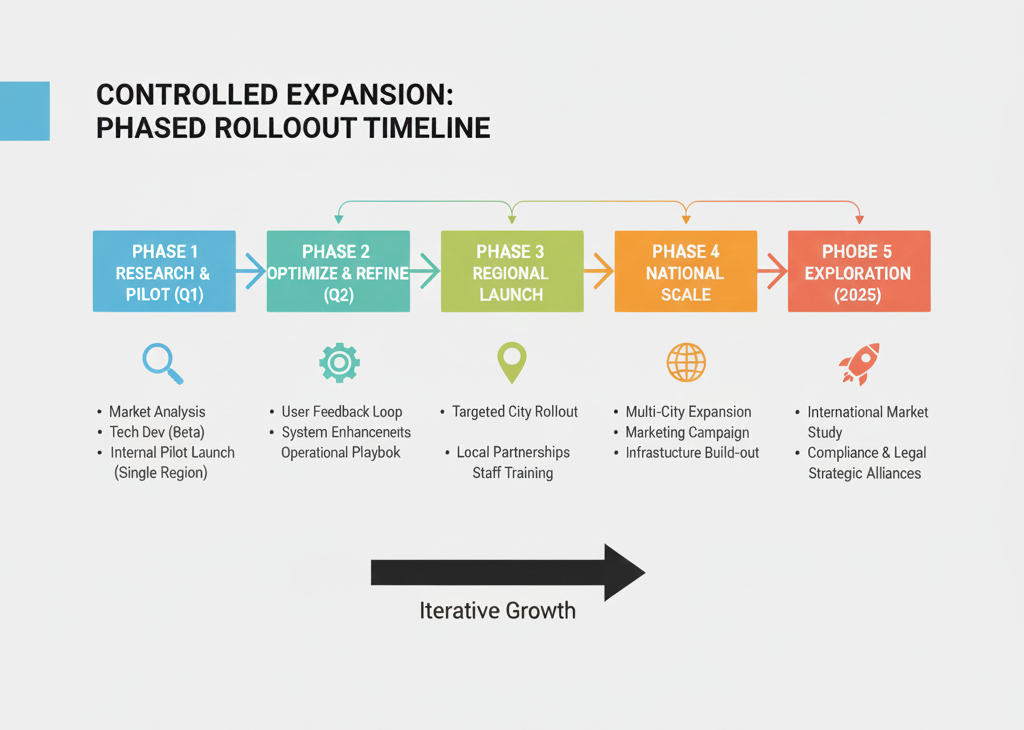

Predictive Maintenance as a Strategic Advantage for IMG Clients

Predictive maintenance, enabled by CMMS, represents a fundamental shift in how facilities are managed—from reactive problem-solving to proactive performance management. For facility leaders, the question is no longer IF predictive maintenance should be adopted, but how well it is executed.

When implemented with the right strategy, data discipline, and operational alignment, CMMS-driven predictive maintenance delivers:

Lower operating costs

Reduced downtime and risk

Longer asset life cycles

Stronger compliance and sustainability outcomes

At Immaculate Management Group (IMG), predictive maintenance aligns directly with our core differentiators: reliability, attention to detail, proactivity, and efficiency. We help organizations move beyond basic maintenance tracking to intelligent, insight-led facility management that supports long-term business goals.

Call to Action

Facility leaders looking to reduce risk, improve uptime, and gain greater control over maintenance performance should consider predictive maintenance as a strategic investment—not just a technical upgrade.

IMG partners with organizations to:

Assess maintenance maturity and readiness

Implement and optimize CMMS platforms

Design scalable predictive maintenance strategies

Translate asset data into actionable operational insights

The future of facility management is predictive. IMG is ready to help you lead that future.

Frequently Asked Questions (FAQ)

What is the difference between predictive maintenance and preventive maintenance?

Preventive maintenance is based on fixed schedules (for example, monthly or quarterly servicing), regardless of asset condition. Predictive maintenance uses real-time and historical asset data—such as usage, performance trends, and condition indicators—to determine when maintenance is actually needed. This reduces unnecessary work while preventing unexpected failures.

Do you need sensors and IoT to run predictive maintenance?

Not always. While sensors and IoT significantly enhance predictive maintenance, many organizations begin using CMMS data alone—such as asset history, failure patterns, and runtime hours. Even without advanced sensors, facilities can achieve meaningful reductions in downtime and reactive maintenance.

How long does it take to see results from predictive maintenance?

Most organizations begin seeing measurable improvements within 3–6 months, particularly in reduced emergency work orders and better maintenance planning. Full ROI, including cost savings and extended asset life, is typically realized within 12–18 months, depending on asset complexity and adoption level.

Is predictive maintenance suitable for small or mid-sized facilities?

Yes. Predictive maintenance is scalable. Small and mid-sized facilities often start by focusing on a limited number of critical assets. CMMS platforms allow organizations to expand their predictive approach gradually without significant upfront complexity or staffing increases.

Image suggestion:

A small-to-mid-size facility using the same CMMS platform as a larger site.

How does predictive maintenance support compliance and audits?

CMMS-enabled predictive maintenance maintains digital records of inspections, service activities, and asset performance. This improves audit readiness, reduces documentation gaps, and helps facilities demonstrate proactive risk management during regulatory reviews.

How does IMG support predictive maintenance implementation?

IMG works with facility leaders to assess maintenance maturity, configure and optimize CMMS platforms, prioritize high-risk assets, and design scalable predictive maintenance strategies. Our focus is not just technology adoption, but long-term operational performance and reliability.